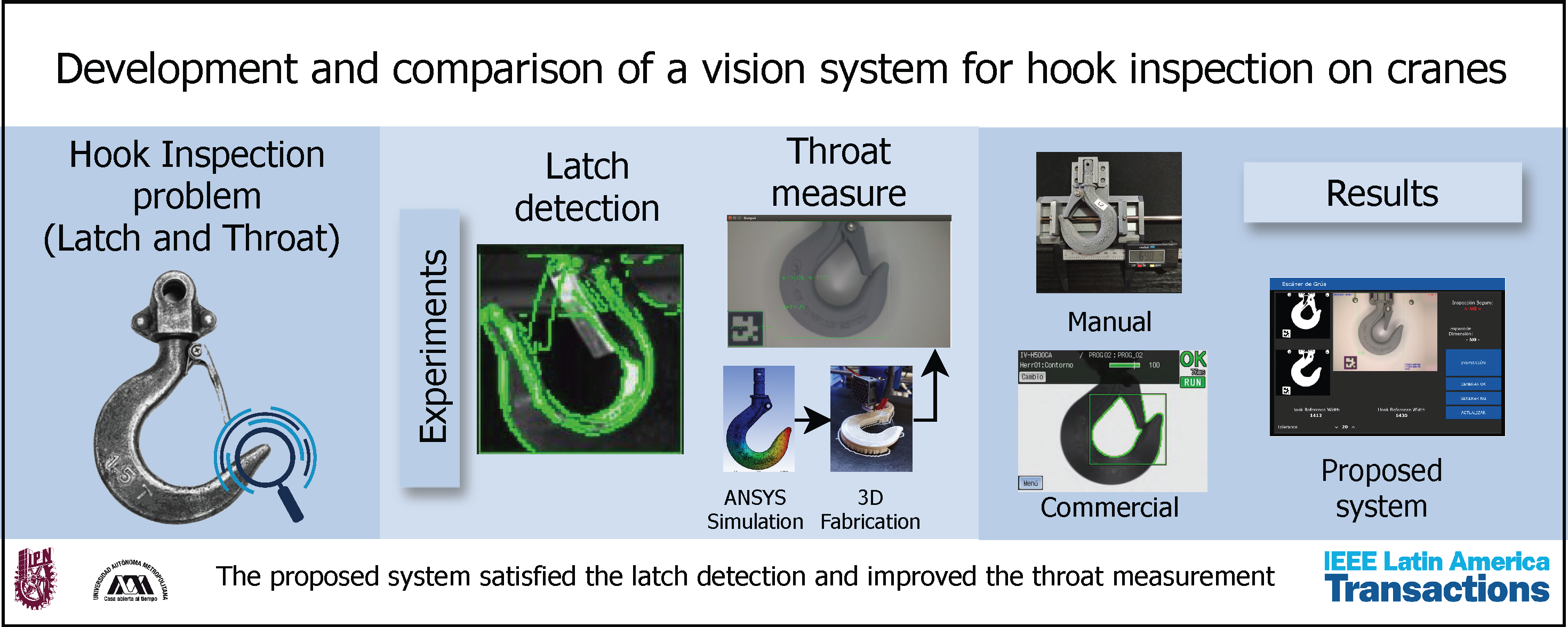

Development and comparison of a vision system for hook inspection on cranes

Keywords:

Computer vision, Crane safety, Hook inspectionAbstract

Overhead cranes are industrial machines that can cause user accidents due to deficiencies in inspecting their various components. One of the activities consists of verifying that the load hook does not exceed the limit deformation. However, the lack of historical records and negligence in visual inspection is a problem to ensure a correct maintenance service. Therefore, the objective of the research was to develop a vision system capable of inspecting, recording, and verifying the hook parameters. The method involved designing a vision module on an integral crane scanner system. A five-state deformation experiment of a cargo hook was modeled with ANSYS and fabricated in 3D printing to validate the proposed module by measuring the parameters manually with a commercial and proprietary vision system. The comparison between the two systems was satisfactory in detecting the latch and the correct position. Finally, the proprietary system improved the resolution up to 0.0435 mm on the hook deformation. With the system’s contribution, it will be possible to know the valuable and safe life of the crane hook by automatic constant inspection.

Downloads

References

Y. Torres, J. Gallardo, J. Domínguez, and F. J. E, “Brittle fracture of a crane hook,” Engineering Failure Analysis, vol. 17, pp. 38–47, Jan.

doi: 10.1016/j.engfailanal.2008.11.011.

M. Zwawi, “Structure integrity and fracture prediction of PLA 3d-printed eye grab hooks with different cross sections,” Procedia Structural Integrity, vol. 37, pp. 1057–1064, 2022. doi: 10.1016/j.prostr.2022.02.045.

K. K. D. Prashant R Mali, “Study of stress analysis of crane hook- a review,” International Journal for Scientific Research and Development, vol. 3, no. 04, 2015.

L. P. K. Mukinay, D. K. Mutombo, C. M. Kalonji, P. K. Ndomatezo, B. M. Kiesse, W. L. Lufumbwa, S. I. Tshimbela, J. M. Lunguya, O. S. Mihigo, and D. K. Ngalamulume, “Non-destructive testings of the lifting hook and heat exchanger circuits of the research reactor TRICO II by liquid penetrant and ultrasonics testing,” Arab Journal of Nuclear Sciences and Applications, vol. 56, pp. 140–148, Jan. 2023. doi: 10.21608/ajnsa.2023.173282.1677.

K. Kishore, V. S. Gujre, S. Choudhary, A. S. Gujre, M. Vishwakarma, T. Thirumurgan, M. Choudhury, M. Adhikary, and A. Kumar, “Failure analysis of a 24 t crane hook using multi-disciplinary approach,” Engineering Failure Analysis, vol. 115, p. 104666, Sept. 2020. doi: 10.1016/j.engfailanal.2020.104666.

W. Li, G. Liu, and Y. Wang, “Machine vision-based hook defect detection,” Journal of Physics: Conference Series, vol. 2435, p. 012002, Feb. 2023. doi: https://dx.doi.org/10.1088/1742-6596/2435/1/012002.

K. He, G. Gkioxari, P. Dollár, and R. Girshick, “Mask r-cnn,” in Proceedings of the IEEE international conference on computer vision, pp. 2961–2969, 2017.

M. Kalaitzakis, B. Cain, S. Carroll, A. Ambrosi, C. Whitehead, and N. Vitzilaios, “Fiducial markers for pose estimation,” Journal of Intelligent and Robotic Systems, vol. 101, Mar. 2021. doi: 10.1007/s10846-020-01307-9.

Keyence, ¿Que es un sensor? Sensor Basics. Comprensión de los principios y características fundamentales, 2020.

American Society of Mechanical Engineers, ASME B30.10-2019. Hooks. Safety Standard for Cableways, Cranes, Derricks, Hoists, Hooks, Jacks, and Slings, 2019.

Neko, “Nekotec manufactura | nosotros,” 2024.

nvidia, “Kit para desarrolladores jetson nano de 2gb,” 2023.

A. Kurniawan, IoT Projects with NVIDIA Jetson Nano. Apress, Dec. 2020.

H. Padmasiri, J. Shashirangana, D. Meedeniya, O. Rana, and C. Perera, “Automated license plate recognition for resource-constrained environments,” Sensors, vol. 22, no. 4, 2022. doi: 10.3390/s22041434.

L. A. Tovar-Ortiz, M. Hernández-Bolaños, and J. Sandoval-Gutiérrez, “Inspección de gancho de carga de una grúa viajera por medio de un sistema de visión artificial,” Boletín UPIITA, vol. 91, July 2022.