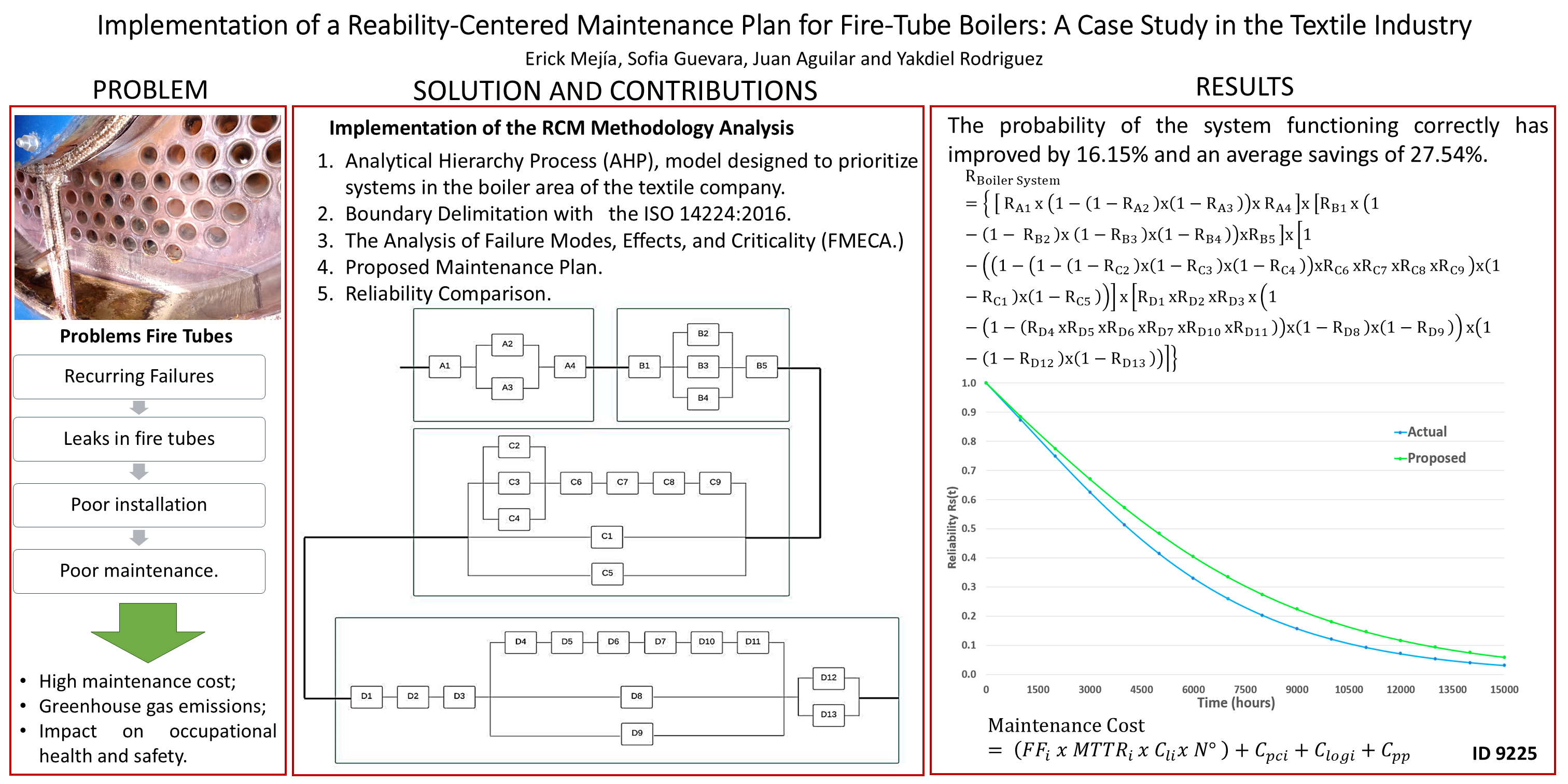

Implementation of a Reliability-Centered Maintenance Plan for Fire-Tube Boilers: A Case Study in the Textile Industry

Keywords:

Maintenance Plan, RCM, Reliability, Fire-Tube Boilers, Textile IndustryAbstract

Reliability-Centered Maintenance (RCM) application in steam systems aims to prevent potential failures by understanding their causes and consequences and determining necessary actions to preserve physical assets. The textile company frequently experiences unplanned stoppages due to steam boiler failures. This study proposes implementing an RCM plan to optimize the maintenance program for fire-tube boilers. A criticality analysis of boiler area equipment was conducted using the Analytical Hierarchy Process (AHP). Failure modes and effects were assessed, and the Risk Weighting Number (RWN) was calculated. Maintenance tasks were assigned using the RCM diagram based on the RWN value. The reliability block diagram of the boiler system was designed, and optimal time intervals were determined using the Weibull distribution for critical components. The literature review found no prior studies applying RCM to fire-tube boilers in the textile industry. The proposed maintenance plan's reliability, availability, and economic viability were assessed in a case study, showing a 16.15% increase in reliability and a 0.004% increase in availability. Additionally, annual maintenance cost savings of up to 27.54% could be achieved. This novel RCM methodology optimizes fire-tube boiler maintenance plans, overcomes classical model limitations, and underscores the importance of reliability analysis for effective preventive maintenance, with potential applications to other systems in the textile industry.

Downloads

References

M. Barma, R. Saidur, S. Rahman, A. Allouhi, B. Akash, and S. M. Sait,“A review on boilers energy use, energy savings, and emissions reductions,”Renewable and Sustainable Energy Reviews, vol. 79, pp. 970–983, 2017. doi:10.1016/j.rser.2017.05.187.

R. V. Filkoski, A. M. Lazarevska, D. Mladenovska, and D. Kitanovski,“Steam system optimization of an industrial heat and powerplant,” Thermal Science, vol. 24, no. 6 Part A, pp. 3649–3662, 2020.doi:10.2298/TSCI200403284F.

A. Hasanbeigi and M. J. S. Zuberi, “Electrification of steam and thermal oil boilers in the textile industry: Techno-economic analysis for china, japan, and taiwan,” Energies, vol. 15, no. 23, p. 9179, 2022. doi:10.3390/en15239179.

S. S. Patil, A. K. Bewoor, and R. B. Patil, “Availability analysis of a steam boiler in textile process industries using failure and repair data: a case study,” ASCE-ASME Journal of Risk and Uncertainty in Engineering Systems, Part B: Mechanical Engineering, vol. 7, no. 2, p. 021002, 2021. doi:10.1115/1.4049007.

J. Geisbush and S. T. Ariaratnam, “Reliability centered maintenance (rcm): literature review of current industry state of practice,” Journal of Quality in Maintenance Engineering, vol. 29, no. 2, pp. 313–337, 2023. doi:10.1108/JQME-02-2021-0018.

L. Pinciroli, P. Baraldi, and E. Zio, “Maintenance optimization in industry 4.0,” Reliability Engineering System Safety, vol. 234, p. 109204, 2023. doi:10.1016/j.ress.2023.109204.

M. Elwardany, “Enhancing steam boiler efficiency through comprehensive energy and exergy analysis: A review,” Process Safety and Environmental Protection, 2024. doi:10.1016/j.psep.2024.01.102.

F. Piechnicki, C. Santos, E. Loures, and E. Santos, “RCM deployment analysis in fiber wood production: improving the productivity and increasing the system reliability,” Independent Journal of Management & Production, vol. 10, no. 6, pp. 2148–2168, 2019. doi:10.14807/ijmp.v10i6.1009.

J. Moubray, “Mantenimiento centrado en confiabilidad,” Gran Bretana: Aladon ltda, 2004.

S. Moradi-Sarvestani, M. R. Dehbozorgi, and M. Rastegar, “A three stage reliability-centered framework for critical feeder identification, failure modes prioritization, and optimal maintenance strategy assignment in power distribution system,” Electric Power Systems Research, vol. 230, p. 110215, 2024. doi:10.1016/j.epsr.2024.110215.

M. C. Jena, S. K. Mishra, and H. S. Moharana, “Integration of industry 4.0 with reliability centered maintenance to enhance sustainable manufacturing,”Environmental Progress & Sustainable Energy, vol. 43, no. 2, p. e14321, 2024. doi:10.1002/ep.14321.

S. S. Patil, A. K. Bewoor, R. Kumar, M. H. Ahmadi, M. Sharifpur, and S. PraveenKumar, “Development of Optimized Maintenance Program for a Steam Boiler System Using Reliability-Centered Maintenance Approach,” Sustainability, vol. 14, p. 10073, Jan. 2022. doi:10.3390/su141610073.

S. S. Patil and A. K. Bewoor, “Reliability analysis of a steam boiler system by expert judgment method and best-fit failure model method: a new approach,” International Journal of Quality & Reliability Management, vol. 38, no. 1, pp. 389–409, 2020. doi:10.1108/IJQRM-01-2020-0023.

S. S. Patil, A. K. Bewoor, R. B. Patil, R. Kumar, B. Ongar, Y. Sarsenbayev, S. PraveenKumar, A. M. M. Ibrahim, M. S. Alsoufi, and A. Elsheikh, “A new approach for failure modes, effects, and criticality analysis using exj-psi model—a case study on boiler system,” Applied Sciences, vol. 12, no. 22, p. 11419, 2022. doi:10.3390/app122211419.

S. S. Patil and A. K. Bewoor, “Optimization of maintenance strategies for steam boiler system using reliability-centered maintenance (rcm) model–a case study from indian textile industries,” International Journal of Quality & Reliability Management, vol. 39, no. 7, pp. 1745–1765, 2022. doi:10.1108/IJQRM-07-2021-0216.

S. S. Patil, A. K. Bewoor, R. Kumar, and I. K. Iliev, “Development of reliability block diagram (rbd) model for reliability analysis of a steam boiler system,” in Predictive Analytics in System Reliability, pp. 137–148, Springer, 2022. doi:10.1007/978-3-031-05347-4_9.

H. P. Jagtap and A. K. Bewoor, “Use of analytic hierarchy process methodology for criticality analysis of thermal power plant equipments,”Materials today: proceedings, vol. 4, no. 2, pp. 1927–1936, 2017. doi:10.1016/j.matpr.2017.02.038.

T. Committee, “ISO 14224:2016,” 2016. https://www.iso.org/standard/64076.html.

D. Priyanta, M. Zaman, et al., “The application of oreda (offshore reliability data) in developing valve criticality analysis criteria,” in IOP Conference Series: Earth and Environmental Science, vol. 1298, p. 012015, IOP Publishing, 2024. doi:10.1088/1755-1315/1298/1/012015.

M. Alrifaey, T. Sai Hong, A. As’ arry, E. Elianddy Supeni, and C. K. Ang, “Optimization and selection of maintenance policies in an electrical gas turbine generator based on the hybrid reliability-centered maintenance (RCM) model,” Processes, vol. 8, no. 6, p. 670, 2020.

doi:10.3390/pr8060670.

T. L. Saaty, “How to make a decision: the analytic hierarchy process,”European journal of operational research, vol. 48, no. 1, pp. 9–26, 1990. doi:10.1016/0377-2217(90)90057-I.

C. Parra and A. Crespo, “Metodos de analisis de criticidad y jerarquización de activos,” Sevilla, Espana: INGEMAN, 2012.

M. Guil Bozal, “Escala mixta likert-thurstone,” Anduli, 5, 81-95., 2006.

P. L. Ramos, D. C. Nascimento, C. Cocolo, M. J. Nicola, C. Alonso, L. G. Ribeiro, A. Ennes, and F. Louzada, “Reliability-centered maintenance: Analyzing failure in harvest sugarcane machine using some generalizations of the weibull distribution,” Modelling and Simulation in Engineering, vol. 2018, no. 1, p. 1241856, 2018. doi:10.1155/2018/1241856.

A. Alebrant Mendes and J. L. Duarte Ribeiro, “Establishment of a maintenance plan based on quantitative analysis in the context of RCM in a JIT production scenario,” Reliability Engineering & System Safety, vol. 127, pp. 21–29, July 2014. doi:10.1016/j.ress.2014.03.004.

S. Chandrasekaran and V. Kiran, “Effects of failure severity and critical failure modes on reliability and availability,” International Review of Mechanical Engineering (IREME), vol. 15, no. 2, 2021. doi:10.15866/ireme.v15i2.19831.