Digital Twin Implementation for an Additive Manufacturing Robotic Cell based on the ISO 23247 Standard

Keywords:

Digital Twin, Robotic cell, Metal, Additive Manufacturing, MQTT, ISO 23247, Industry 4.0Abstract

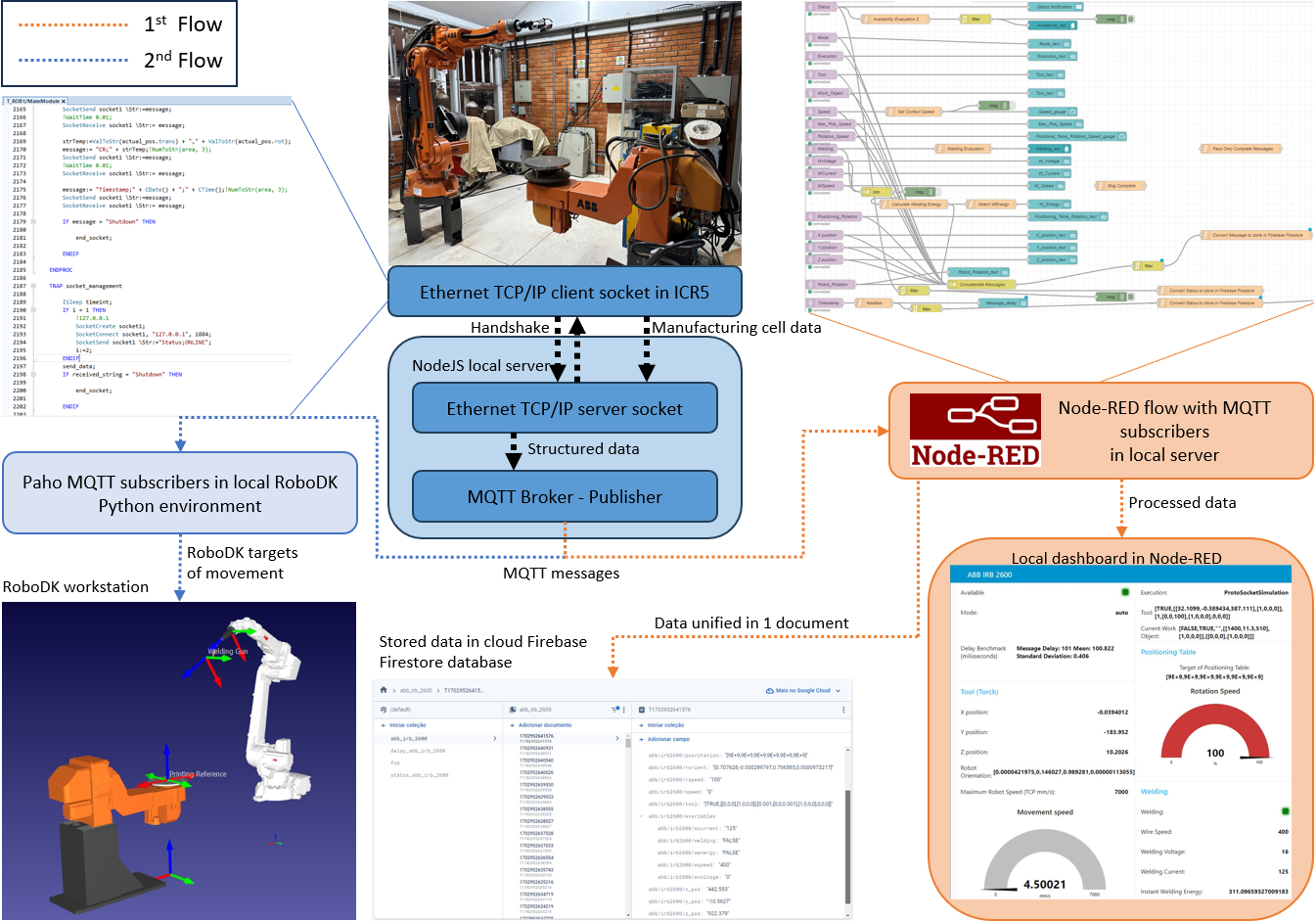

Recent developments in the field of Additive Manufacturing have been improving the capabilities of the technique not only to be able to build complex geometry parts layer by layer with different materials, but also including the so-called Industry 4.0 technologies, namely Internet of Things (IoT), big data (BD) and Digital Twins (DT). The combination of these technologies with Additive Manufacturing allows online process monitoring and simulation, along with the cloud storage of the process and geometry data collected during the material deposition. The analysis of such data allows online and post-deposition identification of eventual process instabilities that can lead to quality problems. Considering the above-mentioned concepts, this work presents a DT architecture based on the ISO 23247-Digital Twin Framework for Manufacturing standard. In this sense, an approach of a Digital Twin framework for metal additive manufacturing process in a robotic cell composed of a robotic arm, positioning table and welding machine is presented and validated, focusing on the collection and cloud storage of both geometrical and process data along with near real-time process simulation.

Downloads

References

A. Haleem and M. Javaid, “Additive manufacturing applications in industry 4.0: A review,” Journal of Industrial Integration and Management, vol. 04, 08 2019. doi: 10.1142/S2424862219300011

S. Chandrasekaran, “Chapter 2 - functionally graded materials for marine risers**this chapter is co-authored by dr. hari sreenivasan, assistant professor, school of petroleum technology, pandit deendayal petroleum university, gandhinagar. india.” in Design of Marine Risers with Functionally Graded Materials, ser. Woodhead Publishing Series in Civil and Structural Engineering, S. Chandrasekaran, Ed. Woodhead Publishing, 2021, pp. 25–58. [Online]. Available: https://doi.org/10.1016/B978-0-12-823537-9.00004-9

P. Ghosal, M. C. Majumder, and A. Chattopadhyay, “Study on direct laser metal deposition,” Materials Today: Proceedings, vol. 5, pp. 12 509–12 518, 2018. doi: https://doi.org/10.1016/j.matpr.2018.02.232

P. Dutta Pramanik, B. Mukherjee, S. Pal, B. Upadhyaya, and S. Dutta, Ubiquitous Manufacturing in the Age of Industry 4.0: A State-of-the-Art Primer, 11 2019, pp. 73–112. [Online]. Available: https://doi.org/10.1007/978-3-030-14544-6_5

B. P. Santos, F. C. Santos, and T. M. Lima, “Industry 4.0: an overview,” 07 2018.

R. S. Peres, X. Jia, J. Lee, K. Sun, A. W. Colombo, and J. Barata, “Industrial artificial intelligence in industry 4.0 - systematic review, challenges and outlook,” IEEE Access, vol. 8, pp. 220 121–220 139, 2020. doi: 10.1109/ACCESS.2020.3042874

M. Singh, R. Srivastava, E. Fuenmayor, V. Kuts, Y. Qiao, N. Murray, and D. Devine, “Applications of digital twin across industries: A review,” Applied Sciences, vol. 12, no. 11, 2022. doi: 10.3390/app12115727

ISO 23247-1, “Automation systems and integration — digital twin framework for manufacturing — part 1: Overview and general principles,” 2021.

T. Shen and B. Li, “Digital twins in additive manufacturing: a state-of-the-art review,” The International Journal of Advanced Manufacturing Technology, Feb 2024. doi: 10.1007/s00170-024-13092-y

J. V. A. Cabral, E. A. R. Gasca, and A. J. Alvares, “Digital twin implementation for machining center based on iso 23247 standard, ”IEEE Latin America Transactions, vol. 21, no. 5, p. 628–635, Apr. 2023. doi: 10.1109/TLA.2023.10130834

R. Singh, “3 - welding and joining processes,” in Applied Welding Engineering (Third Edition), third edition ed., R. Singh, Ed. Butterworth-Heinemann, 2020, pp. 157–186.

P. Stavropoulos, “Digitization of manufacturing processes: From sensing to twining,” Technologies, vol. 10, no. 5, 2022. doi: 10.3390/technologies10050098. [Online]. Available: https://www.mdpi.com/2227-7080/10/5/98

E. Monroy Cruz, L. R. García Carrillo, and L. A. Cruz Salazar, “Structuring cyber-physical systems for distributed control with iec 61499 standard,” IEEE Latin America Transactions, vol. 21, no. 2, p. 251–259, Sep. 2022. doi: 10.1109/TLA.2023.10015217

D. Kim, G. Shao, and G. Jo, “A digital twin implementation architecture for wire + arc additive manufacturing based on iso 23247,” 2022-08-20 04:08:00 2022. doi: https://doi.org/10.1016/j.mfglet.2022.08.008

C. Liu, L. Le Roux, C. Körner, O. Tabaste, F. Lacan, and S. Bigot, “Digital twin-enabled collaborative data management for metal additive manufacturing systems,” Journal of Manufacturing Systems, vol. 62, pp. 857–874, 2022. doi: https://doi.org/10.1016/j.jmsy.2020.05.010

A. Alvares, I. Lacroix, M. Maron, and B. Figueroa, “Robotic additive manufacturing by laser metal deposition in the context of industry 4. 0: Manufatura aditiva robotizada por deposição de metal a laser no contexto da indústria 4. 0,” Concilium, vol. 23, no. 23, p. 79–103, dez. 2023. doi: 10.53660/CLM-2571-23U13

A. J. Alvares, I. Lacroix, M. A. d. L. Maron, and B. S. Figueroa, “Desenvolvimento de uma célula de manufatura aditiva robotizada baseada no processo deposição de metal à laser usando arame de soldagem,” Peer Review, vol. 5, no. 21, p. 17–39, out. 2023. doi: 10.53660/1102.prw2664

Z. Huang, Y. Shen, J. Li, M. Fey, and C. Brecher, “A survey on ai- driven digital twins in industry 4.0: Smart manufacturing and advanced robotics,” Sensors, vol. 21, no. 19, 2021. doi: 10.3390/s21196340

H. Mu, F. He, L. Yuan, P. Commins, H. Wang, and Z. Pan, “Toward a smart wire arc additive manufacturing system: A review on current developments and a framework of digital twin, ”Journal of Manufacturing Systems, vol. 67, pp. 174–189, 2023. doi: https://doi.org/10.1016/j.jmsy.2023.01.012. [Online]. Available: https://www.sciencedirect.com/science/article/pii/S0278612523000237

O. MQTT, “Mqtt: The standard for iot messaging,” https://mqtt.org/.

A. J. Alvares, G. C. De Carvalho, and J. V. A. Cabral, “Mqtt adapter for abb icr5 controller,” https://tinyurl.com/5n8hfamy, 2024.

J. V. A. Cabral, “Abb irb 2600 digital twin demonstration,” https://youtu.be/UGdrRNocmDg, 2024.

H. Li, X. Shi, B. Wu, D. R. Corradi, Z. Pan, and H. Li, “Wire arc additive manufacturing: A review on digital twinning and visualization process,” Journal of Manufacturing Processes, vol. 116, pp. 293–305, 2024. doi: https://doi.org/10.1016/j.jmapro.2024.03.001. [Online]. Available: https://www.sciencedirect.com/science/article/pii/S152661252400210X