Random forest for generating recommendations for predicting copper recovery by flotation

Keywords:

Machine learning, Data science, flotation, predictive model, industry 4.0Abstract

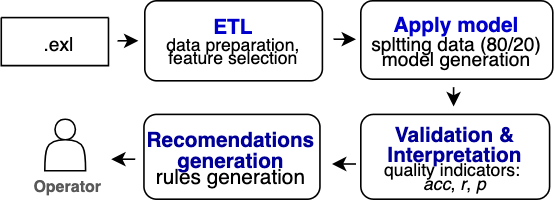

In the copper mining industry, Data Science (DS) techniques and Machine Learning (ML) methods are contributing to improve the prediction of results in industrial processes. In this paper, an experience of applying both DS techniques and a ML algorithm, using historical data from the flotation process is described. These data were collected using a prototype of flotation equipment developed at the Universidad Católica del Norte, in Antofagasta, Chile. To achieve the result an Extraction, Transformation and Load (ETL) process was made. Also, for both, improving the understanding of domain dynamics and selecting the most relevant predictive variables in the flotation process, a Random Forest (FR) model was developed. The combination of these previous results made it possible to generate recommendations on the management of predictor variables to improve copper recovery in the context of the flotation equipment prototype. In this document, the methodological details are presented, and the process used to obtain the aforementioned results is described. As progress was made through 2 iterations, the quality of the results obtained with the predictive model, generated by RF, was improving. At the end of the process, an accuracy of 94,44% was achieved, with an accuracy in each of the classes greater than 90%. These results demonstrate the effectiveness and outstanding performance of the predictive model. These values are highly competitive when compared to those obtained in other similar studies in the context of Industry 4.0.

Downloads

References

M. Abedini, M. Ziaii, T. Timkin, A. Pour, “Machine Learning (ML)-Based Copper Mineralization Prospectivity Mapping (MPM) Using Mining Geochemistry Method and Remote Sensing Satellite Data”. Remote Sensing, vol. 15, no. 15, pp. 1-12, 2023, doi: 10.3390/rs15153708.

P. Katila, C.J. Colfer, W. De Jong, G.Galloway, P. Pacheco, G. Winkel. Sustainable development goals. Report 2022. Cambridge University Press. 2022, doi: 10.1017/9781009210058.

X. Wang, P. Chen, C. Chow, D. Lau, "Artificial-intelligence-led revolution of construction materials: From molecules to Industry 4.0". Matter, vol. 6, no. 6, pp. 1831-1859, 2023, doi: 10.1016/j.matt.2023.04.016.

V. Flores, C. Leiva, "A comparative study on supervised machine learning algorithms for copper recovery quality prediction in a leaching process". Sensors, vol. 21, no. 6, pp. 1-20. 2021, doi: 10.3390/s21062119

A. Patel, N.C. Debnath, "Data Science with Semantic Technologies: New Trends and Future Developments". In: CRC Press ed. 2023, doi: 10.1201/9781003310785.

Z. Wang, D. He, Z. Wang, Q. Li, "Timeliness and Stability-Based Operation Optimization for Copper Flotation Industrial Process" in IEEE Transactions on Instrumentation and Measurement, 72, 1-12. 2023, doi: 10.1109/TIM.2022.3225924.

C. Li, T. Shen, Y. Zhou, "EMPC of aluminium wire and copper terminal for electric vehicles. Materials and Manufacturing Processes, vol. 38, no. 4, pp. 1-8. 2022, doi: 10.1080/10426914.2022.2105890.

P. Putra, A. Azanuddin, B. Purba, Y. Dalimunthe. “Random Forest and decision tree algorithms for car price prediction". Journal Matematika Dan Ilmu Pengetahuan Alam LLDikti Wilayah 1 (JUMPA), 3(2), 81-89. 2023. doi: 10.54076/jumpa.v3i2.305

L. Pinto, C Rojas, L. Torres, "Operación y puesta en marcha de planta piloto de extracción por solvente mediante hollow drop", Capstone Project undergraduate thesis, Universidad Católica del Norte, Antofagasta. 2021.

R. Parvanda, P. Kala, "Trends, opportunities, and challenges in the integration of the additive manufacturing with Industry 4.0.", Progress in Additive Manufacturing, vol. 8, no. 3, pp. 587-614. 2022, doi: 10.1007/s40964-022-00351-1.

L. Adrianto, S. Ciacci, P. Pfister, S. Hellweg, "Toward sustainable reprocessing and valorization of sulfidic copper tailings: Scenarios and prospective LCA". Science of the Total Environment, vol. 871, pp. 1-13, 2023, doi: 10.1016/j.scitotenv.2023.162038.

M. Yaqot, B. Menezes, R. Franzoi, "Interplaying of industry 4.0 and circular economy in cyber-physical systems towards the mines of the future. In 32nd European Symposium on Computer Aided Process Engineering, vol. 15. Computer aided chemical engineering (Ed.), pp. 1609-1614, 2022, doi: 10.1016/B978-0-323-95879-0.50269-1.

B. Amankwaa-Kyeremeh, J. Zhang, M. Zanin, W. Skinner, R.K. Asamoah. “Feature selection and Gaussian process prediction of rougher copper recovery”. Minerals Engineering, vol. 170, pp. 15-24, 2021, doi: 10.1016/j.mineng.2021.107041.

V. Flores, B. Keith, C. Leiva, "Using artificial intelligence techniques to improve the prediction of copper recovery by leaching", Journal of Sensors, pp. 1-12. 2020, doi: 10.1155/2020/2454875.

D. Seenivasan, "ETL (Extract, Transform, Load) Best Practices". International Journal of Computer Trends and Technology, vol. 71, no. 1, pp. 40-44, 2023, doi: 10.14445/22312803/IJCTT-V71I1P106.

P. Gundarapu, "Industry 4.0: Data and Data Integration". In Big Data Applications in Industry 4.0, ch. 2, pp. 39-54, Auerbach Publications, 2022, doi: 10.1201/9781003175889-2.

A. Shirazi, A. Hezarkhani, A. Shirazy, A. Pour, "Geochemical Modeling of Copper Mineralization Using Geostatistical and Machine Learning Algorithms in the Sahlabad Area, Iran". Minerals, vol. 13, no. 9, pp. 1-27, 2023, doi: 10.3390/min13091133.

T.C. Uyan, K. Otto, M. Silva, E. Armakan, "Industry 4.0 foundry data management and supervised machine learning in low-pressure die casting quality improvement". International Journal of Metalcasting, vol. 17, pp. 414-429, 2023, doi: 10.1007/s40962-022-00783-z.

D. Gyasi-Antwi, O. Apea, "Novel copper-sawdust nanocomposite preparation and evaluation". Results in Chemistry, vol. 5, pp. 1-14, 2023, doi: 10.1016/j.rechem.2022.100741.

Flores, V., Bravo, I., Saavedra, M. “Water Quality Classification and Machine Learning Model for Predicting Water Quality Status-A Study on Loa River Located in an Extremely Arid Environment: Atacama Desert”. Water, vol. 15, no. 16, pp.1-18. 2023, doi: 10.3390/w15162868.

H. Liang, C. Yang, K. Huang, D. Wu, W. Gui, "A transfer predictive control method based on inter-domain mapping learning with application to industrial roasting process". ISA transactions, vol. 134, 472-480. 2023, doi: 10.1016/j.isatra.2022.08.022.

L. Breiman, "Random forests". Machine learning, vol. 45, pp. 5-32, 2001, doi: 10.1023/A:1010933404324.

F. Smarra, G. Di Girolamo, V. De Iuliis, A. Jain, R. Mangharam, A. D'Innocenzo, "Data-driven switching modeling for mpc using regression trees and random forests". Nonlinear Analysis: Hybrid Systems, vol. 36, pp. 1-12, 2020, doi: 10.1016/j.nahs.2020.100882.

B.K. Loveday, C.J. Brouckaert, "An analysis of flotation circuit design principles". The Chemical Engineering Journal, vol. 59, pp. 15-21, 1995, doi: 10.1016/0923-0467(95)03001-8.

S.R. Rao, "Surface Chemistry of Froth Flotation". In: Kluwer Academic/Plenum Publishers (Ed.), 2nd Rev Edition. Ch 1-3, 2003, doi: 10.1007/978-1-4615-7975-5.

M. Saldaña, P. Neira, V. Flores, P. Robles, C. Moraga, "A decision support system for changes in operation modes of the copper heap leaching process". Metals, vol. 11, no. 7, pp. 1-12, 2021, doi: 10.3390/met11071025.

Q. Qin, P. Qi, P. Shi, P. Scott, X. Jiang, "Selection of materials in metal additive manufacturing via three-way decision-making". The International Journal of Advanced Manufacturing Technology, vol. 126, no.3, 1293-1302. 2023. doi: 10.1007/s00170-023-10966-5.

S. Pan, J. Yu, J. Han, Y. Zhang, Q. Peng, M. Yang, X. Liu, "Customized development of promising Cu-Cr-Ni-Co-Si alloys enabled by integrated machine learning and characterization". Acta Materialia, vol. 243, pp. 118-128. 2022, doi: 10.1016/j.actamat.2022.118484.