Cutting Parameters and Material Classification Using Multinomial Logistic Regression

Keywords:

Manufacturing, Monitoring, Acceleration, Sound, Temperature, Supervised Machine LearningAbstract

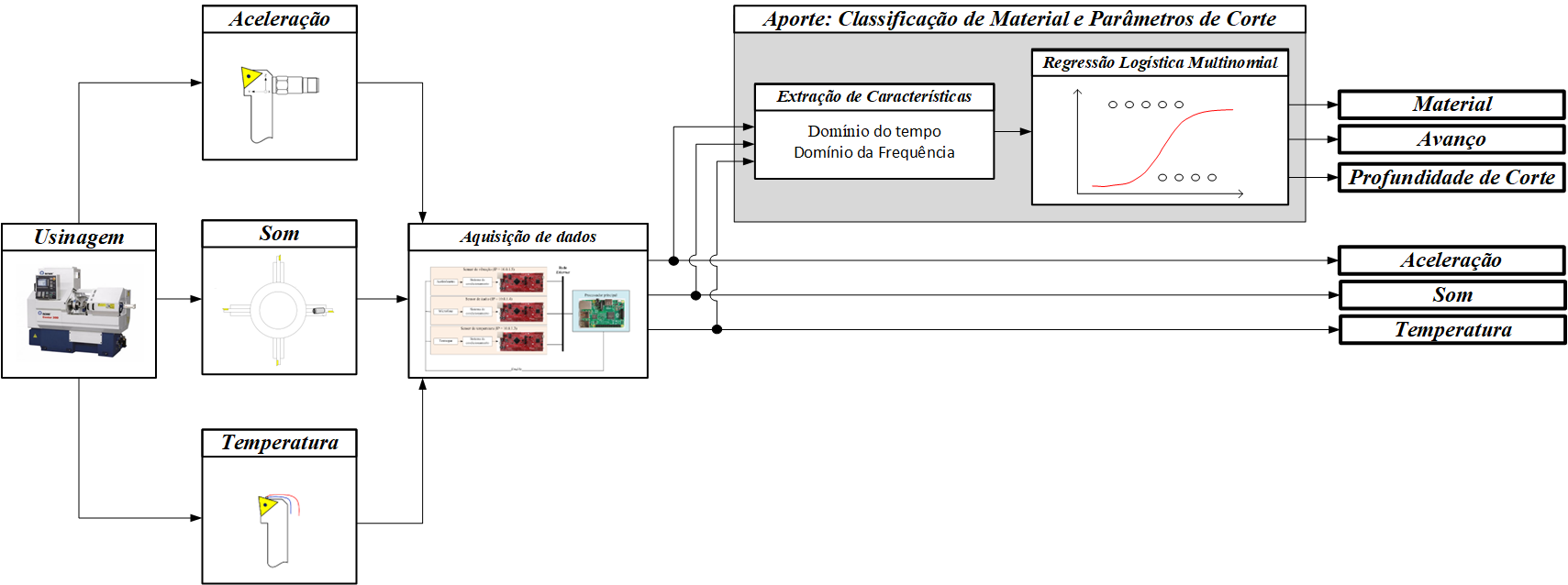

In the context of the new industrial revolution - Industry 4.0, the smart factory concept brought, to manufacturing, the idea of using large amounts of data acquired from a machining process and a set of mathematical techniques, discovering correlations, patterns, or trends in this database. Thus, machine tools are the focus of research in order to monitor and analyze the quality of the machining process based on data from embedded sensors. Based on this strategy, a signature process was created, that consists in capturing behavior patterns of a machine, such as machining conditions, machining quality, or tool wear. This article deal with a comparison between three Multinomial Logistic Regressions: the first using only time domain data, the second using only frequency domain data, and finally, the third using time and frequency domain data to identify the pattern of feed rate, depth of cut, and material being machined. It was observed that the methods had a precision of 96.25%, 37.92%, and 99.58%, respectively, showing that this methodology has great predictive efficiency and could be used to monitor the cutting parameters and material studied in this paper.

Downloads

References

N. Haraguchi, C. F. C. Cheng, and E. Smeets, “The importance of manufacturing in economic development: Has this changed?,” World Development, vol. 93, pp. 293–315, 2017.

N. Marconi, C. F. de Borja Reis, and E. C. de Araújo, “Manufacturing and economic development: The actuality of kaldor’s first and second laws,” Structural Change and Economic Dynamics, vol. 37, pp. 75–89, 2016.

R. Y. Zhong, X. Xu, E. Klotz, and S. T. Newman, “Intelligent manufacturing in the context of industry 4.0: a review,” Engineering, vol. 3, no. 5, pp. 616–630, 2017.

X. Chen, C. Li, Y. Tang, and Q. Xiao, “An internet of things based energy efficiency monitoring and management system for machining workshop,” Journal of cleaner production, vol. 199, pp. 957–968, 2018.

B. Zhang, C. Katinas, and Y. C. Shin, “Robust tool wear monitoring using systematic feature selection in turning processes with consideration of uncertainties,” Journal of Manufacturing Science and Enginee-

ring, vol. 140, no. 8, p. 081010, 2018.

A. Caggiano, “Tool wear prediction in ti-6al-4v machining through multiple sensor monitoring and pca features pattern recognition,” Sensors, vol. 18, no. 3, p. 823, 2018.

E. G. Plaza and P. N. López, “Application of the wavelet packet transform to vibration signals for surface roughness monitoring in cnc turning operations,” Mechanical Systems and Signal Processing, vol. 98,

pp. 902–919, 2018.

M. Kunto ̆glu, A. Aslan, H. Sa ̆glam, D. Y. Pimenov, K. Giasin, and T. Mikolajczyk, “Optimization and analysis of surface roughness, flank wear and 5 different sensorial data via tool condition monitoring system in turning of aisi 5140,” Sensors, vol. 20, no. 16, p. 4377, 2020.

A. Angelopoulos, E. T. Michailidis, N. Nomikos, P. Trakadas, A. Hatziefremidis, S. Voliotis, and T. Zahariadis, “Tackling faults in the industry 4.0 era—a survey of machine-learning solutions and key aspects,” Sensors, vol. 20, no. 1, p. 109, 2020.

D.-H. Kim, T. J. Kim, X. Wang, M. Kim, Y.-J. Quan, J. W. Oh, S.-H. Min, H. Kim, B. Bhandari, I. Yang, et al., “Smart machining process using machine learning: A review and perspective on machining industry,” International Journal of Precision Engineering and Manufacturing-Green Technology, vol. 5, no. 4, pp. 555–568, 2018.

D. Mourtzis, N. Milas, and N. Athinaios, “Towards machine shop 4.0: a general machine model for cnc machine-tools through opc-ua,” Procedia CIRP, vol. 78, pp. 301–306, 2018.

W. Liu, C. Kong, Q. Niu, J. Jiang, and X. Zhou, “A method of nc machine tools intelligent monitoring system in smart factories,” Robotics and computer-integrated manufacturing, vol. 61, p. 101842, 2020.

V. Nasir, M. Kooshkbaghi, J. Cool, and F. Sassani, “Cutting tool temperature monitoring in circular sawing: measurement and multi-sensor feature fusion-based prediction,” The International Journal of

Advanced Manufacturing Technology, vol. 112, no. 9, pp. 2413–2424, 2021.

M. de Oliveira Moreira, A. M. Abrão, R. A. Ferreira, and M. P. Porto, “Temperature monitoring of milling processes using a directional-spectral thermal radiation heat transfer formulation and thermography,”

International Journal of Heat and Mass Transfer, vol. 171, p. 121051, 2021.

L. Bonacini, “Sistema dedicado de aquisição de dados para obtenção de assinaturas de processo em torno cnc,” Master’s thesis, Universidade de São Paulo.

A. K. Kaminise, G. Guimarães, and M. B. da Silva, “Development of a tool–work thermocouple calibration system with physical compensation to study the influence of tool-holder material on cutting temperature in machining,” The International Journal of Advanced Manufacturing Technology, vol. 73, no. 5-8, pp. 735–747, 2014.

Y. S. Ahmed, A. Arif, and S. C. Veldhuis, “Application of the wavelet transform to acoustic emission signals for built-up edge monitoring in stainless steel machining,” Measurement, vol. 154, p. 107478, 2020.

Y. Zhou, B. Sun, W. Sun, and Z. Lei, “Tool wear condition monitoring based on a two-layer angle kernel extreme learning machine using sound sensor for milling process,” Journal of Intelligent Manufacturing, pp. 1–12, 2020.