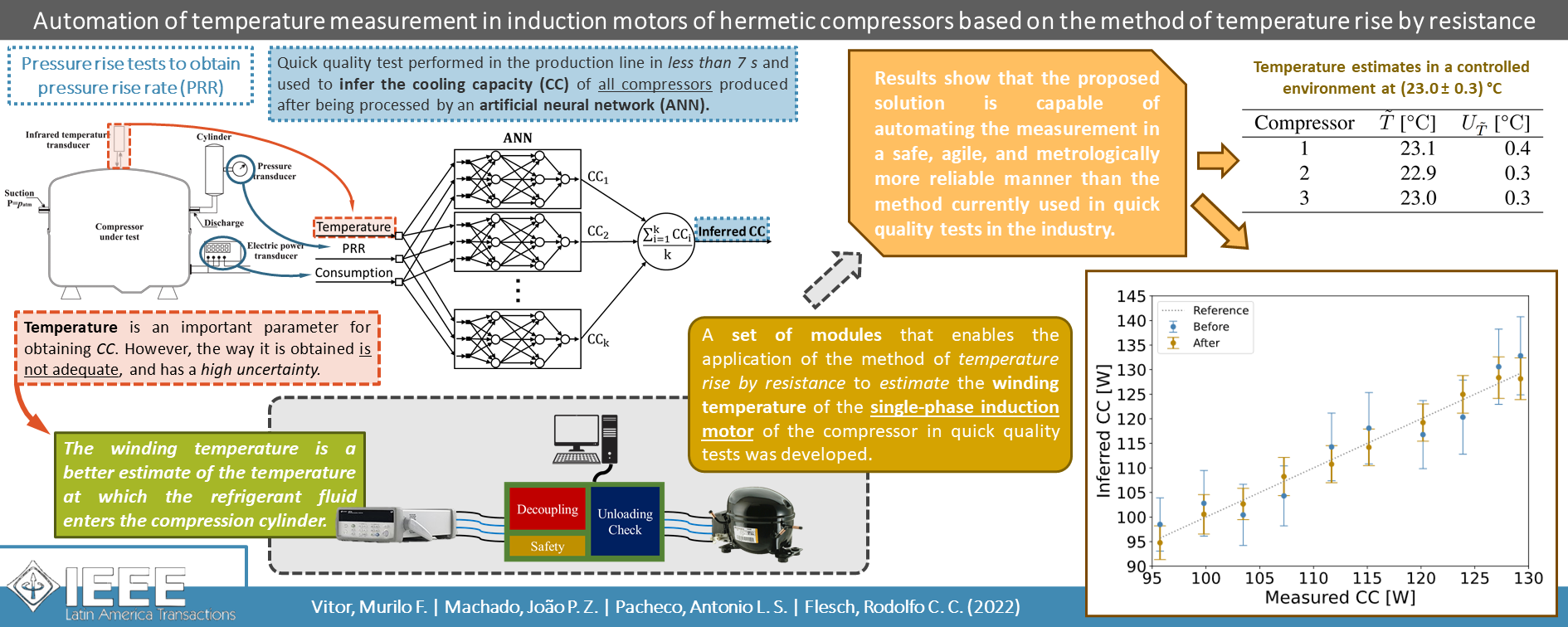

Automation of Temperature Measurement in Induction Motors of Hermetic Compressors Based on the Method of Temperature Rise by Resistance

Keywords:

Compressors, Cooling capacity, Electrical resistance measurement, Single-phase induction motors, Temperature measurement, Temperature rise by resistanceAbstract

Recent studies have proposed the use of artificial neural networks to establish a correlation between the cooling capacity of refrigeration compressors and the results of quick production quality tests. However, the temperature measurement method used in the tests reflects a high uncertainty in the estimated performance parameters, primarily because the measurement is performed on the compressor shell, which has large thermal inertia and does not accurately reflect the temperature changes observed during the tests. This study proposes a set of modules that allow the application of the method of temperature rise by resistance to estimate the winding temperature of the single-phase induction motor of the compressor in quick quality tests. The winding temperature is a better estimate of the temperature at which the refrigerant fluid enters the compression cylinder and its use solves many of the problems associated with the traditional method. Validation tests show that the proposed solution is capable of automating the measurement in a safe, agile, and metrologically more reliable manner than the method currently used in quick quality tests in the industry.

Downloads

References

J. M. Belman-Flores, J. M. Barroso-Maldonado, A. P. Rodríguez-Muñoz, and G. Camacho-Vázquez, “Enhancements in domestic refrigeration, approaching a sustainable refrigerator – a review,” Renew. Sust. Energ. Rev., vol. 51, pp. 955–968, Nov. 2015. doi:10.1016/j.rser.2015.07.003.

“Testing of refrigerant compressors,” 1989.

R. Coral, C. A. Flesch, C. A. Penz, and M. R. Borges, “Development of a committee of artificial neural networks for the performance testing of compressors for thermal machines in very reduced times,” Metrol. Meas. Syst., vol. 22, pp. 79–88, Mar. 2015. doi:10.1515/mms-2015-0003.

R. C. C. Flesch and J. E. Normey-Rico, “Modelling, identification and control of a calorimeter used for performance evaluation of refrigerant compressors,” Control Eng. Pract., vol. 18, pp. 254–261, Mar. 2010. doi:10.1016/j.conengprac.2009.11.003.

R. Coral, C. A. Flesch, and R. C. C. Flesch, “Measurement of refrigeration capacity of compressors with metrological reliability using artificial neural networks,” IEEE Trans. Ind. Electron., vol. 66, pp. 9928–9936, Dec. 2019. doi:10.1109/TIE.2019.2898613.

A. L. S. Pacheco, R. C. C. Flesch, C. A. Flesch, L. A. Iervolino, and V. T. Barros, “Tool based on artificial neural networks to obtain cooling

capacity of hermetic compressors through tests performed in production lines,” Expert Syst. Appl., vol. 194, pp. 116494–116510, May 2022. doi:10.1016/j.eswa.2021.116494.

T. Dutra and C. J. Deschamps, “A simulation approach for hermetic reciprocating compressors including electrical motor mod-

eling,” Int. J. Refrig., vol. 59, pp. 168 – 181, Nov. 2015. doi:10.1016/j.ijrefrig.2015.07.023.

A. Nikbakhsh, H. R. Izadfar, and M. Jazaeri, “Classification and comparison of rotor temperature estimation methods of squirrel cage

induction motors,” Measurement, vol. 145, pp. 779 – 802, Oct. 2019. doi:10.1016/j.measurement.2019.03.072.

X. Liang, “Temperature estimation and vibration monitoring for induction motors and the potential application in electrical submersible motors,” Can. J. Electr. Comput. Eng., vol. 42, pp. 148–162, Jul. 2019. doi:10.1109/CJECE.2018.2875111.

Y. Huang and C. Gühmann, “Temperature estimation of induction machines based on wireless sensor networks,” J. Sens. Sens. Syst., vol. 7, pp. 267–280, Apr. 2018. doi:10.5194/jsss-7-267-2018.

E. Armando, A. Boglietti, F. Mandrile, E. Carpaneto, S. Rubino, and D. G. Nair, “Definition and experimental validation of a second-order thermal model for electrical machines,” IEEE Trans. Ind. Appl., vol. 57, pp. 5969–5982, Dec. 2021. doi:10.1109/TIA.2021.3114131.

B. Groschup, M. Nell, F. Pauli, and K. Hameyer, “Characteristic thermal parameters in electric motors: Comparison between induction- and permanent magnet excited machine,” IEEE Trans. Energy Convers., vol. 36, pp. 2239–2248, Sept. 2021. doi:10.1109/TEC.2021.3056771.

M. O. Sonnaillon, G. Bisheimer, C. De Angelo, and G. O. García, “Online sensorless induction motor temperature monitoring,”

IEEE Trans. Energy Convers., vol. 25, pp. 273–280, Mar. 2010. doi:10.1109/TEC.2010.2042220.

L. He, S. Cheng, Y. Du, R. G. Harley, and T. G. Habetler, “Stator temperature estimation of direct-torque-controlled induction machines via active flux or torque injection,” IEEE Trans. Power Electron., vol. 30, pp. 888–899, Feb. 2015. doi:10.1109/TPEL.2014.2310902.

IEEE, “IEEE 112 - IEEE standard test procedure for polyphase induction motors and generators,” 2017.

R. McElveen, M. Melfi, and J. McFarland, “Improved characterization of polyphase induction motor losses: Test standards must be modified to improve efficiency optimization,” IEEE Ind. Appl. Mag., vol. 25, pp. 61–68, Dec. 2019. doi:10.1109/MIAS.2018.2875208.

R. F. McElveen and C. A. Stockton, “Stator winding temperature rise testing for medium and large polyphase induction motors investigated,” in 2019 IEEE Petroleum and Chemical Industry Conference (PCIC), pp. 83–92, Sept. 2019. doi:10.1109/PCIC30934.2019.9074541.

G. Beges, “Influence of resistance method on motor winding temperature rise measurement,” Int. J. Thermophys., vol. 32, pp. 2333–2342, Oct. 2011. doi:10.1007/s10765-011-1121-9.

M. C. Diniz, C. Melo, and C. J. Deschamps, “Experimental performance assessment of a hermetic reciprocating compressor operating in a household refrigerator under on–off cycling conditions,” Int. J. Refrig., vol. 88, pp. 587–598, Apr. 2018. doi:10.1016/j.ijrefrig.2018.03.024.

Y. Xia, Y. Han, Y. Xu, and M. Ai, “Analyzing temperature rise and fluid flow of high-power-density and high-voltage induction motor in the starting process,” IEEE Access, vol. 7, pp. 35588–35595, Mar. 2019. doi:10.1109/ACCESS.2019.2899346.

E. R. Summers, “Determination of temperature rise of induction motors,” Electr. Eng., vol. 58, pp. 459–467, Sept. 1939. doi:10.1109/EE.1939.6431520.

Keysight Technologies, Keysight 34970A - Data Acquisition/Switch Unit Family, 2014.

“Uncertainty of measurement — part 3: Guide to the expression of uncertainty in measurement (GUM:1995). Supplement 1: Propagation of distributions using a Monte Carlo method,” 2008.

M. G. Cox and B. R. L. Siebert, “The use of a Monte Carlo method for evaluating uncertainty and expanded uncertainty,” Metrologia, vol. 43, pp. S178–S188, Aug. 2006. doi:10.1088/0026-1394/43/4/S03.