Estimation Of The Energy Saving Potentials In Foundry Industries Based On ISO 50001S

Keywords:

Energy Efficiency, energy man, foundry industry, iso 50001, Energy PlanningAbstract

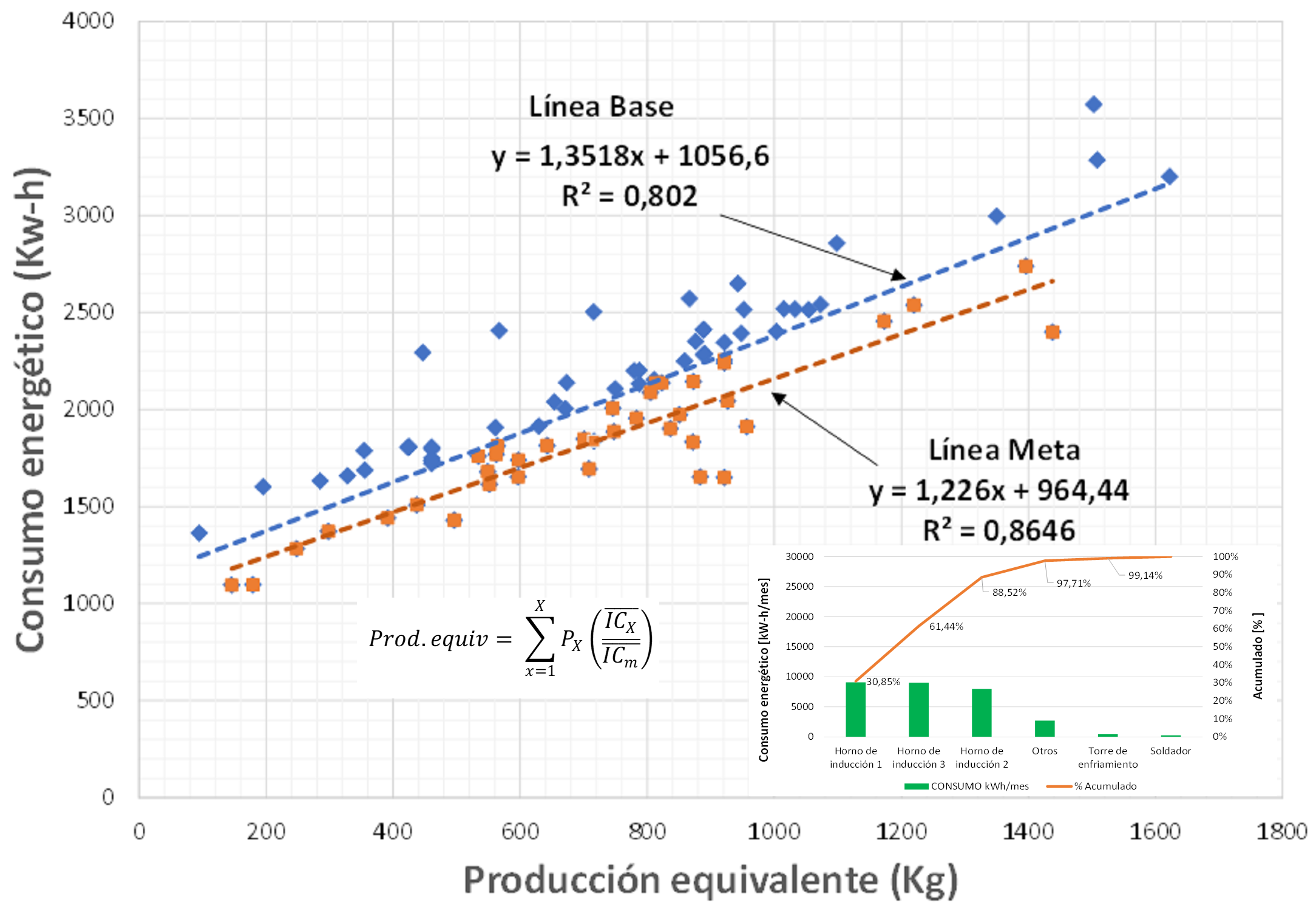

This paper presents the application of tools to develop a procedure to estimate the energy saving potentials in a small foundry company in Colombia, based on the ISO 50001 standard. This work was carried within the framework of a national industrial project, funded by UNIDO, aimed at the small and medium industrial sector companies (SMEs) of Valle del Cauca, to establish the requirements that are needed to implement an energy management system. With the aim of increasing the energy efficiency of the processes, the energy planning process proposed by ISO 50001 is carried out, whose lead to the establishment of concrete and attainable goals, as well as to the proposal of various improvement plans regarding savings and efficient use of energy. As a result, the savings potentials for the different production levels were estimated, which represents a saving of 15984.25 kWh, which corresponds to 8.7% of the total energy consumed in the 10 months analyzed, and a value of 1486 USD

Downloads