Adequate Sensor Placement Method to Ensure Diagnosability

Keywords:

Diagnosability, Fault detection, Modelling, Interpreted Petri Nets, SensorsAbstract

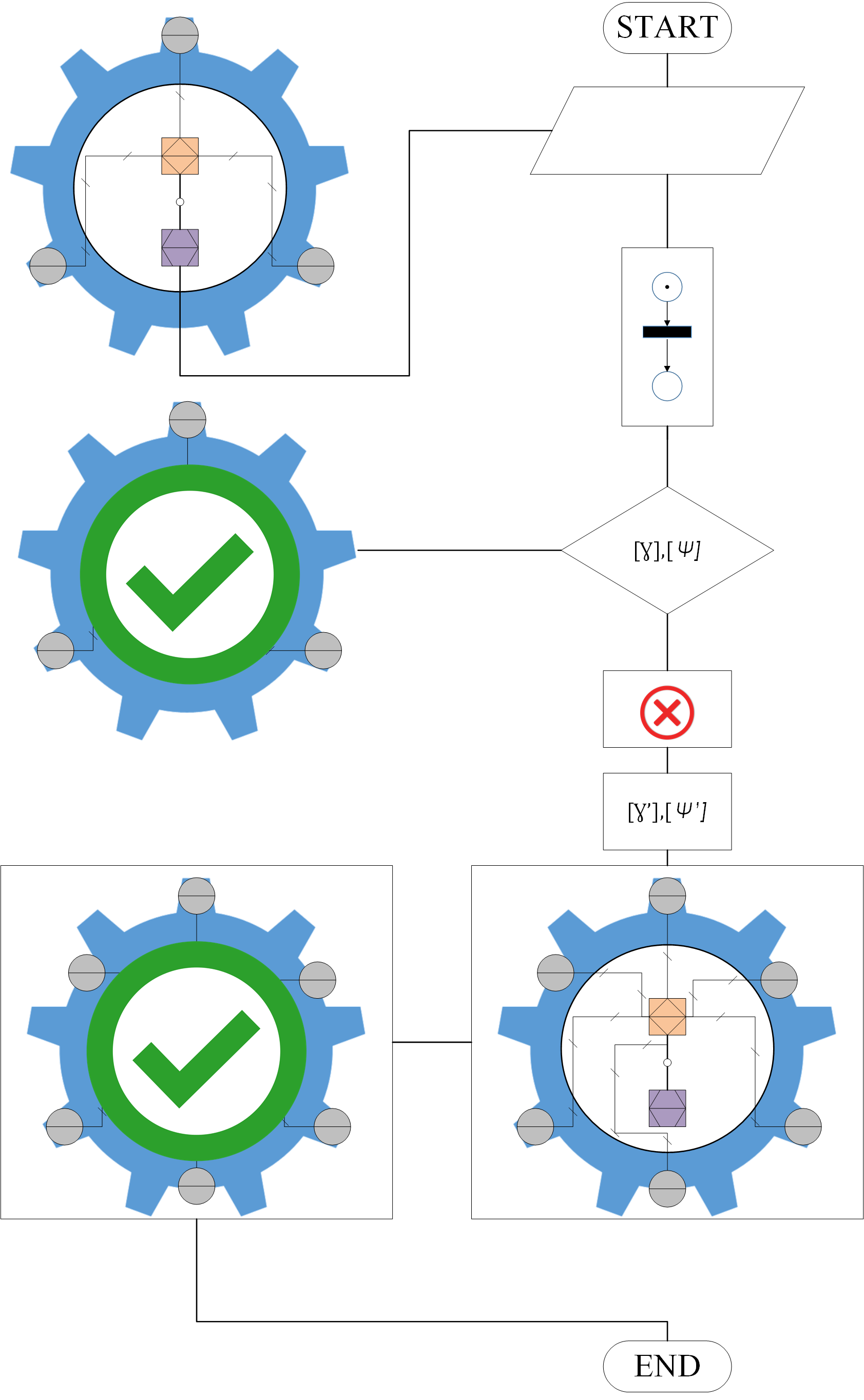

At the industrial level detect and compensate faults in the plant is important, to avoid irreparable damage and the increase of unproductive time, being necessary that the equipment has adequate sensors and plant models analyze the full operation of the system, among other requirements, to obtain under simulation the missing characteristics to diagnose faults. This paper works with the number of sensors in plant to reach diagnosability, for this the modelling is relationed with the acquired signals from the plant, it begins with an input/output identification method modelling by interpreted Petri net, then diagnosability general characteristics was determined and mathematically interrelated; and a sensor placement method for diagnosability was stablished. The sensor placement method stablishes the plant operation points where additional sensors are needed; this process is explained with a simulation example. The investigation result is a minimal sensor set that makes the plant diagnosable, avoiding sensors redundancy and reducing related costs.

Downloads