Safety Aspects in Dry Storage of Spent Nuclear Fuel in Long Term Operation for Brazilian Nuclear Power Plants

Keywords:

Nuclear Power Plant, Spent Nuclear Fuel, Dry Storage Systems, Long Term OperationAbstract

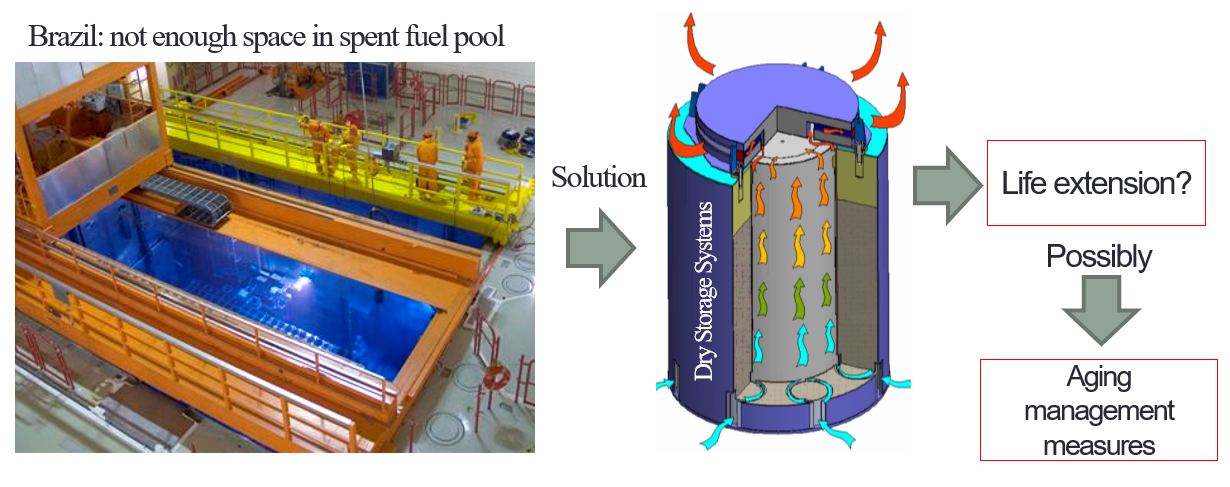

The use of Dry Casks Storage Systems (DCSS) as a strategy for Spent Nuclear Fuel (SNF) management is a solution widely used by several countries. It should be noted that this approach was originally conceived as a temporary / supplementary storage solution, since the ultimate solution is the reprocessing or the storage of SNF in Finals Repositories of radioactive material. Taking into account the limited storage capacity of Angra I and II Spent Fuel Pool, the Nuclear Power Plants Operator has submitted to the Brazilian Nuclear Regulatory Body (CNEN) the design of the Dry Storage Unit (UAS) as an alternative to SNF management. This work performs a Safety Evaluation applying the methodology defined in NUREG 1927 [2]. Three Structures, Systems and Components (SSC), classified as ITS (Important to safety), were selected. Following the methodology, materials and service environments were identified for those SSCs previously selected. In a second moment the ageing mechanisms and degradation effects to be considered in the UAS Long Term Operation were presented. As a result of this Safety Evaluation, some recommendations were extracted. These recommendations together with those found in the literature can guide the regulatory decision-making process regarding to the license renewal of UAS in Brazilian territory.

Downloads

References

Eletrobras Eletronuclear S.A., “Final Safety Analysis Report (FSAR Angra 1e 2)”, ETN, Rio de Janeiro, RJ, Brazil, 2013.

NUREG 1927: Standard Review Plan for Renewal of Specific Licenses and Certificates of Compliance for Dry Storage of Spent Nuclear Fuel, Nuclear Regulatory Commission (NRC), Washington, D.C., 2016. [Online]. Available: https://www.nrc.gov/docs/ML1617/ML16179A148.pdf. Accessed on: Sep. 25, 2019.

Eletrobras Eletronuclear S.A., “Preliminary Safety Analysis Report on The HI-STORM FW MPC Storage System (PSAR UAS)”, ETN, Rio de Janeiro, RJ, Brazil, 2018.

CFR Part 72: Licensing Requirements for the Independent Storage of Spent Nuclear Fuel and High-Level Radioactive Waste, Nuclear Regulatory Commission (NRC), Washington, D.C., 2011. [Online]. Available: https://www.nrc.gov/reading-rm/doc-collections/cfr/part072/, Accessed on: Sep. 25, 2019.

Regulatory Guide 3.62: Standard Format and Content for the Safety Analysis Report for Onsite Storage of Spent Fuel Storage Casks, Nuclear Regulatory Commission (NRC), Washington, D.C., 1989. [Online]. Available: https://www.nrc.gov/docs/ML0037/ML003739545.pdf, Accessed on: Sep. 25, 2019.

NUREG-1567: Standard Review Plan for Spent Fuel Dry Storage Facilities, Nuclear Regulatory Commission (NRC), Washington, D.C., 2000. [Online]. Available: https://www.nrc.gov/reading-rm/doc-collections/nuregs/staff/sr1567/sr1567.pdf. Accessed on: Sep. 25, 2019.

A. Kosaki, “Evaluation method of corrosion lifetime of conventional stainless steel canister under oceanic air environment”, Nuclear Engineering and Design, vol. 238, pp. 1233-1240. 2008.

TANI, Jun-ichi, Mayuzumi, Masami., Hara, Nobuyoshi. Stress corrosion cracking of stainless-steel canister for concrete cask storage of spent fuel”, Journal of Nuclear Materials vol. 379, pp. 42-47, 2008.

L. Caseres; T.S. Mintz, “Atmospheric Stress Corrosion Cracking Susceptibility of Welded and Unwelded 304, 304L, and 316L Austenitic Stainless Steels Commonly Used for Dry Cask Storage Containers Exposed to Marine Environments”, Southwest Research Institute. San Antonio, Texas, 2010.

Spencer, D. T. et al, “The initiation and propagation of chloride-induced trans granular stress corrosion cracking (TGSCC) of 304L austenitic stainless steel under atmospheric conditions”, Corrosion Science., vol. 88, pp.76-88, 2014.

Electric Power Research Institute, “Susceptibility Assessment Criteria for Chloride-Induced Stress Corrosion Cracking (CISCC) of Welded Stainless-Steel Canisters for Dry Cask Storage Systems”, EPRI, Palo Alto, California, USA, Tech. Rep. TR-3002005371, Sep. 2015.

Poškas, R., “Thermal analysis of CASTOR RBMK-1500 casks during long-term storage of spent nuclear fuel”, Annals of Nuclear Energy, vol. 99, pp. 40-46, 2017.

Hanifehzadeh, M., “Multi-hazard performance of reinforced concrete dry casks subjected to chloride attack and tip-over impact”, Annals of Nuclear Energy., vol. 108, pp. 10-23, 2017.

Spykman, G., “Dry storage of spent nuclear fuel and high active waste in Germany-Current situation and technical aspects on inventories integrity for a prolonged storage time”, Nuclear Engineering and Technology. vol. 50, pp. 313-317, 2018.

C. J. Lissenden et al., “Toward Robotic Inspection of Dry Storage Casks for Spent Nuclear Fuel,” ASME. J. Pressure Vessel Technol, vol. 139, no. 3, Jun. 2017. Accessed on: Jun. 9, 2020, DOI: https://doi.org/10.1115/1.4035788.

Levinson, J. S., and Thrun, S., 2010, “Robust Vehicle Localization in Urban Environments Using Probabilistic Maps,” IEEE International Conference on Robotics and Automation (ICRA), Anchorage, AK, May 3–7, pp. 4372–4378.

Standard Practice for Making and Using U-Bend Stress-Corrosion Test Specimens, ASTM G30, 2016.

U.S. Department of Energy – DOE, “Used Fuel Disposition Campaign: Gap Analysis to Support Extended Storage of Used Nuclear Fuel”. Washington, D.C. 2012.

Ito, K. Kamimura; Y. Tsukuda. “Evaluation of Irradiation Effect on Spent Fuel Cladding Creep Properties”. In Proceedings of the 2004 International Meeting on LWR Fuel Performance, American Nuclear Society. La Grange Park, Illinois, USA, 2004, pp. 440.

McRae, G. A.; Coleman, C.E; Leitch, B.W., “The First Step for Delayed Hydride Cracking in Zirconium Alloys”, Journal of Nuclear Materials, vol. 396, pp. 130-143, 2010.

Puls, Manfred P., “Review of the thermodynamic basis for models of delayed hydride cracking rate in zirconium alloys”, Journal of Nuclear Materials. vol. 393, pp. 350-367, 2009.

Rothman, A.J. “Potential Corrosion and Degradation Mechanisms of Zircaloy™ Cladding on Spent Nuclear Fuel in a Tuff Repository”, Lawrence Livermore National Laboratory, Livermore, California, USA, Report Attachment 10 to MRB-0418, JUCID-20172, 1984.

Electric Power Research Institute, “Technical Bases for Extended Dry Storage of Spent Nuclear Fuel”, EPRI, Palo Alto, California, USA, Tech. Rep. TR-1003416, 2002.

Z. D. Thome, W. C. A. Pereira, J. C. Machado, J. M. Seixas and W. Soares-Filho, "A System for Nuclear Fuel Inspection Based on Ultrasonic Pulse-Echo Technique," in IEEE Transactions on Nuclear Science, vol. 58, no. 5, pp. 2452-2458, Oct. 2011, doi: 10.1109/TNS.2011.2164557.